Innovative High-Speed Electric Motor Generators & Magnetic Rotor Gen Sets

Maximizing Efficiency & Power Density in Electric Motors and Generators

Core Advantages of Calnetix's High-Speed Motors and Magnetic Rotor Gen Sets

Calnetix’s high-speed motors, high-speed generators, and magnetic rotor gen sets offer smaller footprints, lighter weight, higher efficiency, higher reliability, and lower maintenance requirements than traditional gearbox machines, setting new standards in magnetic rotor gen set technology. Our electric motors and electric generators range from only a few watts to megawatt power levels with speeds ranging from 4,000 rpm to 450,000 rpm. Calnetix's high-speed motor generators provide the following advantages:

Optimizing High-Speed Motor and Gen Set Operation for Maximum Efficiency

Electric machines can be much smaller and have better efficiency when they can operate at a higher speed than the 3,600 rpm limit imposed by 60 Hz power systems. Solid-state inverters remove the speed limit. The power rating of a given machine increases directly with speed until structural, thermal or dynamic stability limits are reached. A good high-speed design is where these limits are approached in harmony.

By trading speed for torque, solid-state inverters with their unique ability to change the frequency has enabled the following benefits:

-

Ability to greatly reduce the size, complexity and weight of electrical machines

-

Ability to use more robust motor rotors that don’t need insulated windings, slip rings, and sliding contacts (brushes)

-

Ability to accommodate frequencies up to 3,000 Hz

Achieving High Efficiency and Durability in Extreme Temperatures

Proprietary design processes and material selections are utilized to meet the demands of the customer’s application, including efficiency and temperature requirements. The benefits include:

-

Reduced losses at the component level through the use of special coatings and manufacturing methods

-

Ability to operate in harsh ambient environments up to 90⁰C by using thermal management and high-performance encapsulation techniques

Enhancing Power Density for Compact, Powerful Motor Solutions

For applications where light weight is of utmost importance, such as in aerospace and motorsports, Calnetix’s high-speed motors and generators are designed to provide maximum power density while maintaining high operating efficiency and good thermal performance consistent with design requirements. An example of a power dense machine that we have designed and manufactured is rated at 100 kW and weighs 7.7 kg in a 2.3-liter volume, which is equivalent to a machine power density of 13 kW/kg and 43 kW/liter. Calnetix is able to achieve such high-power density due to the following:

-

Optimization of electromagnetic design, including magnetization topologies

-

Optimization of the machine’s L/D (length over diameter) aspect ratio

-

Optimization of the magnetic circuit

-

Selection of materials, including the grade of magnets, the stator laminations and their thickness, the magnet retention sleeve and other materials

Tailoring Motor Performance to Meet Diverse Industrial Applications

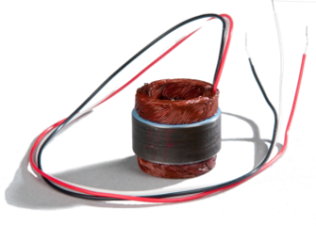

Calnetix’s high-performance motors and generators can be designed along with magnetic bearings and high efficiency variable speed drives (VSD) completely in-house. This enables us to achieve the most compact, optimized solution for each application without compromising any inherit benefits, such as high-speed, high-efficiency operation and zero maintenance requirements. The special construction features and fabrication of our high-performance stators and rotors provide some unique benefits, including:

-

Optimized stator configuration due to utilizing in-house tools, such as fill factor, end-turn bundle and neutral termination techniques

-

High back EMF per magnet volume with high magnetizing efficiency due to the rotor’s ability to magnetically couple to the stator with minimal flux fringing in the axial and transverse directions

-

Minimal rotor harmonic currents due to surface mounting techniques that keep circulating electrical paths isolated without loss of electromagnetic or structural integrity

-

Minimal rotor air gap and air gap cooling requirements due to high strength composite sleeve that has near-zero losses from harmonic eddy currents

-

Advanced electromagnetic efficiency, rotor tip-speeds and industry-leading power densities due to the proprietary technologies in Calnetix’s PM rotors

Customizing High-Speed Motors and Magnetic Rotor Gen Sets for Unique Needs

Calnetix’s high-speed motors and generators provide the best combination of small size, high efficiency and integration flexibility to meet the requirements of special applications and provide unique features and benefits, such as:

-

Hermetical sealing

-

Oil-free operation

-

In-line motor generator configurations

-

Direct mount bearingless motor configurations

Our Cutting-Edge Products: High-Speed Motors, Generators, and Magnetic Rotor Sets

Calnetix’s high-speed motors and generators have been widely used in industrial and defense and aerospace applications due to their high performance and high efficiency. Calnetix’s permanent magnet motor has proven to be highly desirable, not just for efficiency reasons, but also for reliability, elimination of maintenance costs and ease of implementation. The two standard Calnetix high-speed motor generators are shown and described below.

Magnaforce™

Ultraforce™

Magnaforce™

-

Low voltage

-

Less than 1 MW

-

Applications such as chiller systems, compressors, blowers, generators for turboexpanders, blood pumps, electrically assisted turbochargers, UXVs, satellites, test stands, food spray dryers and precision lasers

Why Opt for Calnetix's Permanent Magnet Motors and Magnetic Rotor Gen Sets?

The continuous desire for increased high-power density, oil-free operations, high efficiency and zero emissions are leading to a growing demand for high-speed permanent magnet motors and generators. A high-speed motor or generator combined with active magnetic bearings is a 360-degree solution for increasing energy efficiency, reliability and compactness. Some of the advantages of switching to permanent magnet motors, include:

-

Zero excitation power

-

Efficiency of 95% or higher

-

Smooth rotor

-

Large air gap

-

High resistivity and very low permeability of the rotor

-

Reduced inverter size and losses

-

And many more…

To see more information about permanent magnet machine advantages, click here.

Resources

View More

White Paper

How PM Motor Generators Work

Advantages

Advantages of PM Machines for High-Speed Applications

Technical Paper

Control of a 750kW Permanent Magnet Synchronous Motor

Technical Paper

Demonstrated Operability and Reliability Improvements for a Prototype High-Speed Rotary-Disc Atomizer Supported on Active Magnetic Bearings

Technical Paper

Losses in High Speed Permanent Magnet Machines Used in Microturbine Applications