Overview

High-Speed Air Compressor for Industrial Applications Running on Axially Compact Magnetic Bearings with a Sensor System

Customer Specifications

Our customer, a leader in compression, construction and mining equipment, approached Calnetix to increase the speed of the air compressors in order to expand their product line and to make their products more reliable and efficient. The existing 7 bar compressor system was operating at a maximum of 45,000 rpm. The customer wanted to expand their product line to include higher pressure levels up to 10 bar; this required the motor to spin at high speeds. However, the maximum speed of the motor was limited by the rotordynamic bending mode of the rotor.

Solution

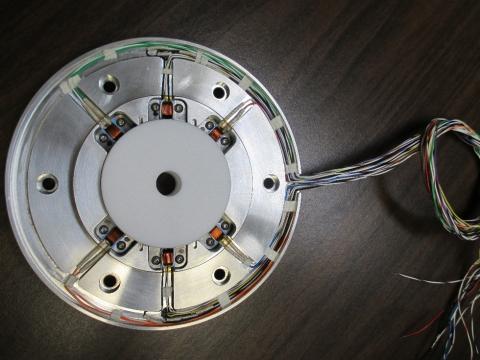

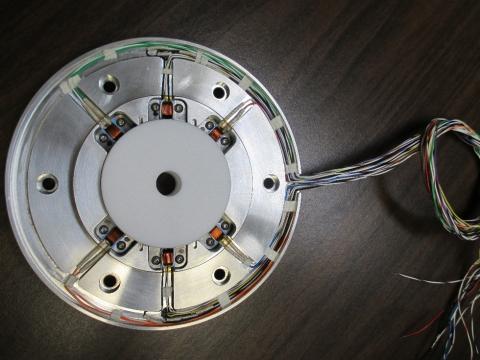

Calnetix technology was leveraged to co-develop a compact machine that can spin to a higher speed. A Side-by-Side magnetic bearing combo actuator was used as an axially compact solution for a thrust and radial actuator combination with no crosstalk between control axes. The edge sensor allowed for an axial compact packaging of Calnetix’s radial and axial sensors while the radial and axial sensors used the same target on the rotor. The speed sensor was integrated into the radial dead pole without taking any additional axial space in the machine. Calnetix’s carbon fiber sleeving technology created a thin and robust magnet retention with better rotor gap cooling.

Challenges

The magnetic bearing system had to be axially compact to allow more rotordynamic margin at higher speeds. A robust method was required to retain the rotor magnets in order to increase the speed of air compressors while maintaining enough gap for rotor cooling.

Results

Calnetix and the customer entered into a long-term partnership to develop these high-speed systems. The axially compact redesigned machine increased the speed of the oil-free and maintenance-free air compressors from 45,000 rpm to 55,000 rpm, and the sleeving technology offered significant margin to the high-speed application.

Contact Us Today

See what Calnetix’s high-speed solutions can do for your business.